A Practice of the Mundane

Weekly Thoughts

I have spent some time thinking over where we could improve our process as we set up to restock the Run Club Hoodies. When we first released these hoodies in December of 2021, we did so out of my parent's garage. This was our most significant release (at the time) and had multiple moving parts. The most challenging part about the restock was the limited time for prep since Shawn and I both live in NYC, and the product/boxes / envelopes-cards, etc., were all at my parent's house in Virginia.

The biggest bottlenecks seem to come around:

Card & Envelope Prep

While we try to prep these ahead of time, it can be hard to predict how many will be needed, and we ran out of prepped envelopes. This may not seem like a big issue, but the time that it takes to fill an envelope before every order adds up as demands continue to roll in

Box Sizing / Prep

Box sizing is a continual work in progress. Since we ship on a volumetric basis, it's always better to have less "air" volume in the box to keep shipping costs in line with modeled predictions. On top of this, because we were working out of my parent's garage, we couldn't pre-tape a large majority of boxes. This meant that we had to take someone off packing orders to just tape boxes. Each incremental person that is shifted away from packing boxes and into a non-shipping role hurts the speed at which packages get shipped out

Walking time from packaging tables to product

This is something that I continue to try and optimize. We need to minimize walking to grab products for the orders. The less time spent walking, the greater the efficiency of packing the orders.

Work-board week of April 9th, 2022

We have many samples in the works, which will take longer than a week. This means that a week-by-week update may not be possible.

The tote bag is entering rework as we optimize it for production. The factory let us know that (as it was constructed for the sample) it would be inefficient to do in full production. This is a normal process for us since the sample serves as a way to get an idea into a tangible product. We will try our best to maintain the integrity of the design. The most significant change will be a reduction of the rivets.

I spent some time brainstorming the fashion show. Without giving up too much (and obviously, ideas can change), I want the experience to be tangible for the viewers. My initial idea follows the lifecycle of a garment through the different stages of human life. More on this later as it continues to get flushed out.

Five different trouser fabrics have arrived at the factory in NYC (the fabrics that I showed last week). We will begin production on those. The women's sizes for the patterns are undergoing a pattern rework to ensure that there is not too much fabric through the seat/butt of the trouser.

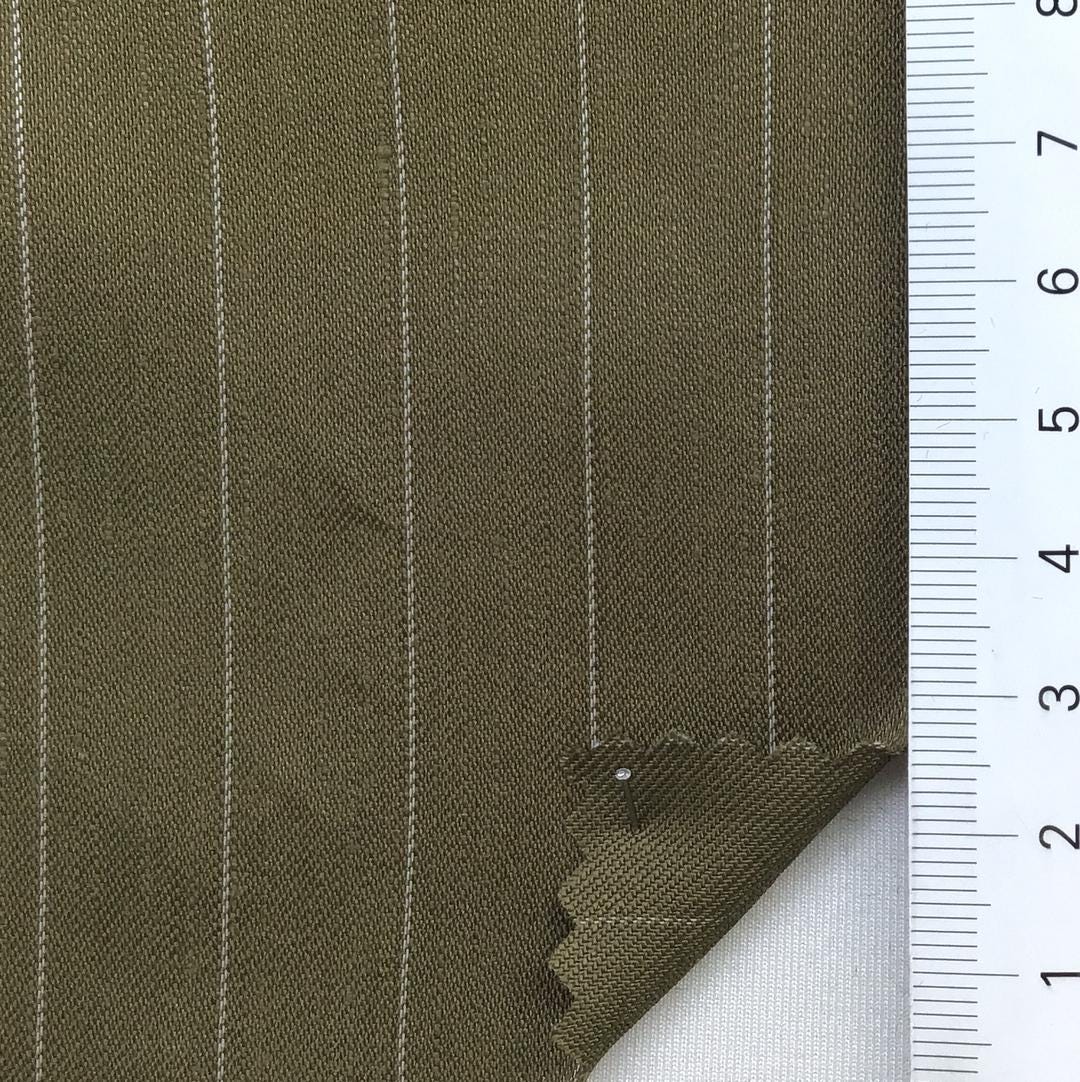

I am continue to source new fabrics (a few below). Mainly trouser fabrics;

Training

A successful week of both running and lifting, finishing off with a solid 13-mile run today. The weather was beautiful (for the first time in a while).

I have had increased focus and intensity in the gym. I am trying to figure out the cause, and I assume it has something to do with the reduction in weekly mileage (46 miles per week).

Articles I found interesting this week (clickable):

Have a great week everyone!

-Marcus

As a buying costumer and huge supporter of minted, the hand written cards add such a costumer satisfaction and customer guarantee. Not only the card in the order but the Christmas cards really set you apart from other brands and made a strong connection with a customer/community member.