FINALE: Bag Saga

As someone who has been quite adamant about trying to manufacture items here in NYC, I figured it might be helpful to break down the costs of bringing a project to life.

Firstly, you'll have to find the right factory to do the work. In our case, we started in LA (failed), then tried Detroit (failed), and ultimately landed in our backyard in NYC. I will do my best to include every cost of this venture to paint you the most transparent picture possible.

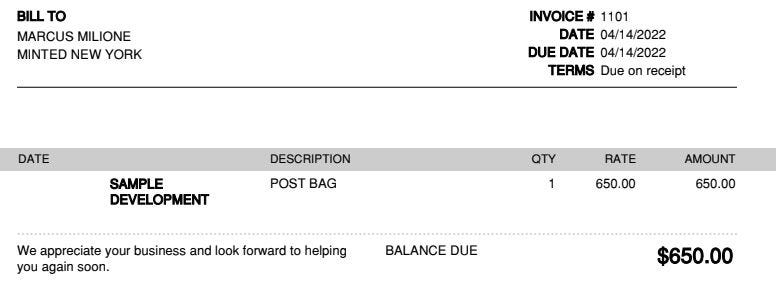

To sample in Los Angeles, we paid $650 in sampling costs and $24.30 in shipping (so you can inspect the bag in hand).

Total cost so far: $674.3

When the bag arrives, we realize we are far off the mark. The biggest issue for us was that we let the factory change the pattern to make things easier to produce, which, after agreeing, meant that we would lose many aspects of the bag that made it unique.

My gut feeling told me it would take many rounds of sampling (with the LA factory) to get the bag right, so I chose to locate a new factory that may produce something closer to the original sample on the first try.

Round 2:

We reviewed what needed to be done and sent them the original sample Clay had made for us to reference. Upon looking at the sample and estimating the work required, we received our next invoice, which was considerably more than the first.

After receiving the sample, I was more frustrated than the first time. This time - liberty was taken with the pattern/design, citing impossibilities in our original work. While I found it hard to believe, I am happy that we were not promised one thing and then delivered something very different.

Cost for sample two: $3,561.25

Total cost so far: $4,235.55

After some discussion with Clay and Shawn, we figured that the only way to get this bag right would be to have the factory in NYC. This would allow us to be hands-on during the entire process and adequately explain what we want the end product to look like, all while considering the necessary changes needed for a full production run.

The third time is the charm:

We landed on a local factory here in the NYC garment district. After meeting with the owner and explaining the original sample and design, I could tell he understood what we were after. He explained that while some things must be changed to make a streamlined production possible, most of the original detailing and structure can be maintained. This gave me great hope and new excitement about moving forward.

We needed custom hardware to fit the bag's oversized strap. This involved its own sampling process, but for the sake of time, I will file all of that under "hardware," which you can see below.

All in all, the third sample cost $1,900 (+ cutting dies, which = $1,900, as seen in the last image of this post) or $3,800.

That brings sampling costs (call it… R&D) to $8,035.55. Those are the hard costs; the only thing missing is labor costs, which I will leave out because there is no good way to break them down.

After sampling, we move into production. In the USA, I have found that most places require you to source everything yourself (fabric, trims, etc.), whereas the places we have worked with overseas have teams that do a lot of that for you (you can certainly request stuff). This can be a rather large time sink - but again, we will leave labor costs out.

Per bag, we need each of the following:

Canvas fabric (2 yards/ bag): $16.8/bag

The Riri zippers: $18.56/bag

Custom hardware (2pcs/bag): $1.42

Labor: $120/bag

Total cost: $156.78/bag

Total cost w/ sample costs: $172.85

With the writing of this post, I hope that people interested in making (anything) get a better understanding of the different steps taken to reach a final product. Making products locally in NYC (or the USA, for that matter) tends to come at a higher cost than in many other places. It is my hope that we can continue to do business with local factories and support the economies of makers in the USA and NYC alike.

In a similar fashion to the early access email signup, if you have made it this far and would like a discount on the bag, please use code: minutes at checkout. We have a few bags left, and I am unsure when a restocking will happen.

Be well

Marcus

A good relationship with a manufacturer goes a long way. The final product shows that. Love the bag

The journey of this bag has been a fun one to watch. Can't imagine the feeling of releasing such a quality item after all of that work! Not to mention everything else you guys create/inspire/marathon training/etc. Nobody does it better.